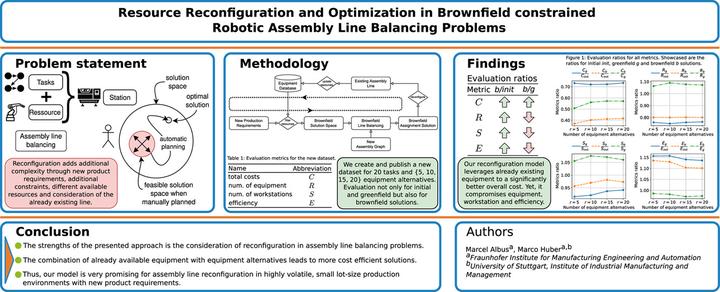

Resource reconfiguration and optimization in brownfield constrained Robotic Assembly Line Balancing Problems

Marcel Albus

Marcel AlbusAbstract

Successful operation of an assembly line requires balancing work among resources and stations of the line to minimize costs, a problem known as the Assembly Line Balancing Problem (ALBP). Most work in literature considers new production facilities where no resources are available beforehand, known as a greenfield approach. However, reconfiguration required by volatile market demands necessitates assembly line and production capability changes. This reconfigurable production paradigm imposes new constraints on the ALBP. In this paper, we propose an integer-programming-based optimization for solving the dynamic resource reconfiguration for automatic assembly lines. We evaluate our approach on a newly developed multi-cost resource-constrained reconfiguration benchmark dataset, which includes information of an already existing line. Our model achieves, on average, a 1.9× better total assembly line cost compared to an optimized greenfield approach. However, it compromises the number of workstations and line efficiency. This model attempts to enable reconfigurable production and decrease production costs in automatic assembly lines while increasing sustainability.